Sheet metal manufacturing involves processing metal sheets through techniques such as laser cutting, shearing, bending, stamping, and welding. The workflow includes design drawing, blanking, forming, welding, and surface treatment. Widely used in power, semiconductor, financial equipment, medical, communication, and mechanical equipment industries, it is a key technology in modern manufacturing for achieving lightweight and precision. Production is achieved through molds or CNC equipment to meet diverse functional and aesthetic needs.

The company possesses a complete sheet metal manufacturing process, from raw material entry to final product delivery—all conducted within the factory. Processes include laser cutting, bending, stamping, welding, machining, electroplating, powder coating, and electromechanical assembly, ensuring product quality and production cycle efficiency for optimal customer service.

Laser Cutting

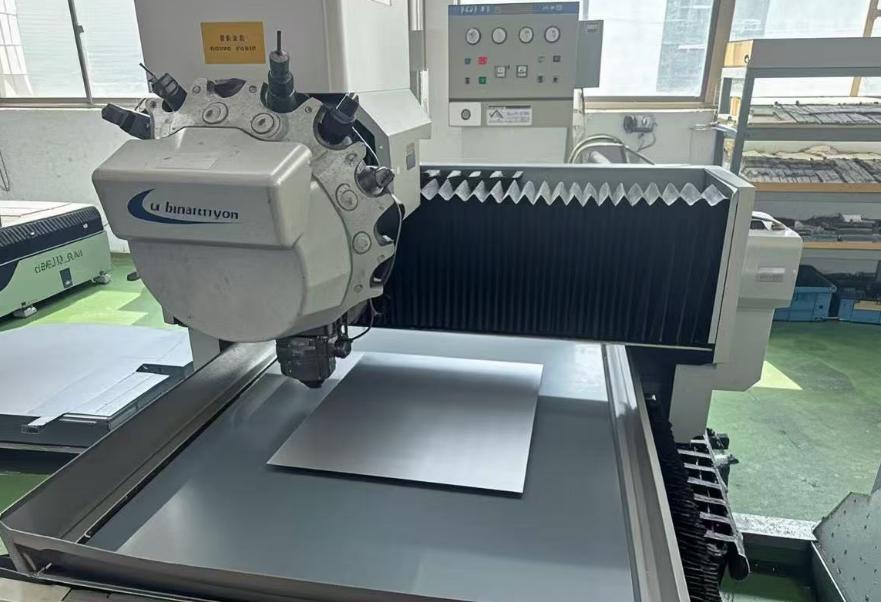

NCT Punching Machines

Automatic Bending

CNC Drilling & Tapping

Robotic Welding

Surface Electroplating

Powder Coating

Quality Control Inspection

3000W-12000W high-precision laser metal sheet cutting machines.

| Device | Specification |

| Fiber Laser Cutting Machines | 3000W—12000W |

| Fiber Laser Engravers | 50W |

High-performance NCT punch presses are capable of efficiently completing punching, blanking, and drawing tasks with high precision and excellent surface quality.

| Device | Specification |

| CNC Punch Presses | 1500mm*3000mm |

| Mechanical Punch Presses | 45T—260T |

Salvagnini automatic bending machines ensure fully automated, high-quality, and efficient production. 35T–250T CNC press brakes provide ample capacity.

| Device | Specification |

| Servo Press Brakes | Imported Auto Benders |

| CNC Press Brakes | 35T—250T |

CNC drilling and tapping centers offer high positional accuracy, automatic tool change, rapid positioning, and high efficiency. Tapping machines provide high thread precision and fast automatic processing, supporting various thread types and materials for stable part assembly quality.

| Device | Specification |

| CNC drilling, tapping and milling center | IDLE-1325 16T |

| Press Riveting Machine | M2.5-M10 |

The company is equipped with welding robots for laser welding, TIG welding, CO2 protection welding, and aluminum alloy welding.

| Device | Specification |

| Laser Welding Robots | 3000W |

| CO2 Welding Robots | 1800mm*2300mm |

| Automatic Stud Welding Machine | 1500mm*2500mm |

| Weld Seam Polishing Machine | 1800mm*2500mm |

| Flat Brushing Machine | W1000mm |

Fully enclosed, unmanned automatic galvanizing lines are capable of producing blue and white zinc finishes per customer needs, meeting 96 to 128 hours salt spray test standards.

| Device | Specification |

| Electroplating Line | 3000mm*750mm*1500mm*56000mm |

| Stainless Steel/Aluminum Cleaning Line | 2400mm*750mm*1500mm*46000mm |

There are two powder coating lines and three vertical curing ovens in ourworkshop. They have immersion pretreatment, and the processes of integratedspraying, drying, and curing. We are capable of handling large - sized productcoating with a uniform and stable finish. We also support silkscreening and paoprinting.

| Device | Specification |

| Coating Line | W=900mm*200000mm |

| Pre-treatment Line | Single slot size: 1300(H) * 2500(L) * 3000(D) · A total of 21 slots |

| Ceramic conversion treatment line | Single slot size: 1300(H) * 2300(L) * 1700(D) · A total of 7 slots |

| Silkscreen/Pad Printing Line | 3500mm*750mm |

| Vertical Coating Line | 6000mm*1500mm*2980mm |

A full-process quality inspection system paired with advanced instruments ensures products meet customer quality requirements. Precision tools include CMMs, ROHS analyzers, CCD optical dimension inspectors, and other devices.

| Device | Specification |

| High-Precision CMM Systems | E=(1.9+3L/1000)um |

| CMM Systems | E=(2.9+4L/1000)um |

| Precision Sheet Metal Vision Inspection System (Planar) | ±50um |

| Element Analyzers | 1-10ppm,RSD<5 |

| X-ray Analyzers | 10-20ppm,RSD<10% |

| Tensile Testers | Load Accuracy±1% |

| Other measurement and testing instruments | ..................... |

Sheet Metal Manufacturing delivers precision engineered components that form the backbone of modern products. Our advanced Sheet Metal Manufacture capabilities transform steel, aluminum, stainless steel, and specialty alloys into durable, high-performance parts. Using laser cutting, CNC punching, bending, welding, and finishing, we produce enclosures, brackets, panels, cabinets, and complex assemblies to exact specifications. Customers benefit from tight tolerances, consistent quality, and scalable production from prototypes to high-volume runs. Custom designs are supported with DFM guidance, rapid lead times, and rigorous quality control. Our Sheet Metal Manufacturing process emphasizes efficiency, material optimization, and surface finishes including powder coating, anodizing, and plating. Ideal for industrial, automotive, electronics, energy, and retail applications, our solutions reduce costs, improve reliability, and accelerate time-to-market. Partner with us for dependable, customizable, and sustainable metal fabrication that meets global standards and your exacting performance needs. Backed by experienced engineers, responsive service, and long-term manufacturing partnerships worldwide globally today.

Sheet metal manufacturing is a core industrial process used to transform flat metal sheets into functional, durable, and precisely engineered products. As a professional sheet metal product manufacturer, we specialize in delivering high-quality standard and fully customized sheet metal solutions. From concept and prototyping to mass production, we accept custom orders for virtually any sheet metal product, tailored to your drawings, samples, or performance requirements.

Sheet metal products are valued for their structural integrity, formability, and adaptability.

Our manufacturing capabilities support both functional industrial parts and visually refined consumer-facing products.

Specifications vary depending on the application and customer requirements.

Laser cutting

CNC punching

Bending and forming

Welding (MIG, TIG, spot welding)

Riveting and assembly

All specifications can be adjusted to meet project-specific standards and compliance requirements.

We also provide technical guidance and documentation for custom-designed products.

Our custom manufacturing approach allows us to serve both specialized niche applications and large industrial projects.

With advanced equipment, experienced engineers, and a flexible production system, we are committed to delivering reliable, cost-effective, and high-quality sheet metal products. Whether you need a single prototype or large-scale production, we welcome custom orders for any sheet metal product and work closely with you to turn ideas into precision-engineered reality.

Thank you for your interest in our products and services. If you have any questions, need additional information, or would like a customized solution, please feel free to contact us. Our team will respond to your inquiry as soon as possible.

Address: NO. 128, Jinxiu Road, Luoxing Street, Jiashan County, Jiaxing, Zhejiang, China

Phone: +86 133-3583-7295

Phone: +86 135-7533-6233

Email: Jason_he@hontechgroup.com

Email: allen_hsu@hontechgroup.com

Website: Customizable Sheet Metal Manufacture Serve

You may also complete the inquiry form below, and one of our representatives will get in touch with you shortly.

We look forward to working with you and building a long-term partnership.